SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT CRUSHERS (VSI)

Sandvik Stationary VSI impact crushers are designed for higher capacity, reduced power consumption, reduced maintenance costs and intervals. In the aggregate, mining and

Sandvik Stationary VSI impact crushers are designed for higher capacity, reduced power consumption, reduced maintenance costs and intervals. In the aggregate, mining and

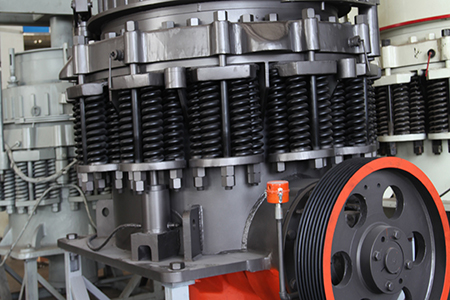

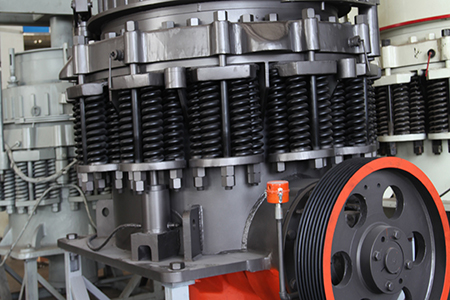

VSI Crushers Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing. These crushers are suitable for a wide range of

SandMax VSI Crushers -- General Application Guidelines REMco VSI SandMax crushers are fully autogenous vertical shaft impact crushers designed to operate as third or fourth stage crushers in the processing of

VSI crushers can be used to create this machine sand but existing mathematical models make it hard to plan new sites and achieve a viable replacement to the natural sand.

VSI Crushers Isc Vsi ISC® VSI Crushers Click below for more information on current ISC® VSI Crusher Models and Capacities. Link To: ISC® VSI Crusher Models and Capacities

SBM VSI Series vertical shaft impact crusher is designed by reputed German expert of SBM and every index is in world’s leading standard. It incorporates three crushing types

Primary Menu VSI Crushers Discover our wide range of vertical shaft impact (VSI) crushers right here. Scroll VSI CRUSHERS When it comes to Vertical Shaft Impactors – Pilot Crushtec has been building, repairing, refining

VSI-crushers – SCP VSI-crushers Vertical Shaft Impactors for cubizising crushed rock. We offer both stationary and mobile cubicators with visibility. 5 models of crushers for

Sandvik Stationary VSI impact crushers are designed for higher capacity and lower power consumption. The autogenous "rock on rock" crushing technique results in several major advantages: Product gradation

CV228 VSI impact crusher. Sandvik CV228 VSI impact crusher is manufactured for tertiary and quaternary applications. It can handle anything from hard and abrasive rocks to soft, moist and even sticky materials. It's

Downloads. Sandvik CV217 VSI can be used for a variety of applications, from quality aggregate production for concrete products, road construction and Dam production, to Mining industries where is's used as a pre-grinder to mills resulting in huge power savings. It gives excellent product shape and are also ideal for crushing minerals, slag ...

VSI crushers can be used to create this machine sand but existing mathematical models make it hard to plan new sites and achieve a viable replacement to the natural sand. In this thesis, the use of vertical shaft impact crushers to crush aggregate rock to rounder particles is investigated.

VSI APPLICATIONS Rock and mineral deposits vary widely from site to site, country to country, and around the world. Crushing plants, circuit variations, and product requirements are infinite. For this reason, any crusher, if it is to suceed, perform reliably and economically, it must be designed to fit the specific needs of your job.

Static VSI Crusher. Terex MPS offer one of the widest range of Vertical Shaft Impactors (VSI) crushers on the market. The Canica brand offers a full range of open shoe table, enclosed rotor and rock self, and rotor and rock box combinations to match production and operational needs.

VSI Crushers Isc Vsi ISC® VSI Crushers Click below for more information on current ISC® VSI Crusher Models and Capacities. Link To: ISC® VSI Crusher Models and

V-Slam™ VSI Models from Stedman are vertical shaft impactors for all your coarse-to-fine crushing needs. VSI crushers offer significant savings over higher-priced competitive crushers. The V-Slam, with its low horsepower per ton of throughput, minimizes operating costs. Our vertical shaft impactors feature multiple rotor configurations for ...

Combining the MV series VSI crusher with a big screen into the same advanced chassis makes it possible to design a perfectly balanced solution that is easy to move. The advanced design rotor comes standard with

Twister VSI crushers use two variations of VSI crushing. The first is vertical shaft impact crushing where rock is fed onto a table type rotor which accelerates and then discharges the rock at high speed against steel

Downloads Sandvik CV228 VSI can be used for a variety of applications, from quality aggregate production for concrete products, road construction and Dam production, to Mining industries where is's used as a pre

VSI Crushers Quality Vertical Shaft Impactors REMco Vertical Shaft Impactors are typically used in the third or fourth stage of crushing circuits. Feed rates are from 15 to 1500 TPH. Machine drive powers range from

Downloads. Sandvik CV217 VSI can be used for a variety of applications, from quality aggregate production for concrete products, road construction and Dam production, to Mining industries where is's used as a pre-grinder to mills resulting in huge power savings. It gives excellent product shape and are also ideal for crushing minerals, slag ...

Impactors (VSI) crushers on the market. Robust VSI crushers are a vital tool for producing highly cubical products in small sizes and eliminating soft material. A properly configured Canica® VSI crusher is the key to minimizing wear costs and downtime – and maximizing profitability. At Canica®, we offer one of

VSI crushers can be used to create this machine sand but existing mathematical models make it hard to plan new sites and achieve a viable replacement to the natural sand. In this thesis, the use of vertical shaft impact crushers to crush aggregate rock to rounder particles is investigated.

Contents Introduction Refresh your VSI operation 4 Competitive advantages offered 5 Orange Series Rotor components 7 Top and bottom wear plates 8 Rotor tips / tip selection guide 9 Cavity wear plates 10 Cavity upper and

V-Slam™ VSI Models from Stedman are vertical shaft impactors for all your coarse-to-fine crushing needs. VSI crushers offer significant savings over higher-priced competitive crushers. The V-Slam, with its low horsepower per ton of throughput, minimizes operating costs. Our vertical shaft impactors feature multiple rotor configurations for ...

Combining the MV series VSI crusher with a big screen into the same advanced chassis makes it possible to design a perfectly balanced solution that is easy to move. The advanced design rotor comes standard with

Twister VSI crushers are designed to crush a wide range of rocks and minerals using rock-on-rock or rock-on-steel crushing principles. Twister VSI crushers use two variations of VSI crushing.

Crushers - VSI Crusher Ore Sizer OM Series VSI Crushers OM50 The Ore Sizer OM 50 is the ideal unit for the small to medium producer with a production capacity for 30 to 150 ton per hour of aggregate and sands depending on installed power. This single drive unit is a very flexible VSI with a choice of four different rotor sizes and configuration.

© Slidesigma - 2022 | All Right Reserved. Designed By Slidesigma