Metallurgical resource recovery from waste

ABSTRACT. Steel slag from an electric arc furnace (EAF) may contain significant amounts of oxides of valuable metals. The recovery of iron

ABSTRACT. Steel slag from an electric arc furnace (EAF) may contain significant amounts of oxides of valuable metals. The recovery of iron

34429031 DOI: 10.1080/09593330.2021.1968957 Abstract Steel slag from an electric arc furnace (EAF) may contain significant amounts of oxides of valuable metals. The

on the extraction of valuable metals from EAF slag. It consists of co-grinding the slag with alkaline reagents (NaOH, KOH and NaOH+ Na 2 CO 3 and KOH + K 2 CO 3) followed

2021年8月1日 EAF slag filters have been utilized for the mitigation of heavy metals from a gypsum mining leachate where a high removal efficiency of 99.9% phosphorus followed

2021年8月25日 The recovery of iron and other metals from the EAF slag using smelt-reduction process was studied with coal as the reductant. A pig iron phase with high

2021年9月1日 The chemical and mineralogical characterization results show that the investigated slags contain approximately 20–22% Fe, 3–4% Cr, 1 500 ppm V and are

2021年10月14日 High-Performance Method of Recovery of Metals from EAF Dust-Processing without Solid Waste Materials License CC BY 4.0 Authors: Stanisław Małecki

Currently, this method is considered for the selective recovery of metals from blast furnace slurries [27,28]. A literature analysis of EAF dust recycling processes allows us to

2021年3月19日 The grown demand of current and future development of new technologies for high added value and strategic metals, such as molybdenum, vanadium, and

2022年12月19日 EAF slag is a rock-like material generated during the steel-making process. Approximately 130 facilities across the United States generate EAF slag. EAF

2021年2月5日 This work concerns the development of a process based on the extraction of valuable metals from EAF slag. It consists of co-grinding the slag with alkaline reagents (NaOH, KOH and NaOH + Na 2 CO 3 and KOH + K 2 CO 3) followed by heating the mixture to 600–800° C and leaching.The valuable metals were recovered by LDH.

Steel slag from an electric arc furnace (EAF) may contain significant amounts of oxides of valuable metals. The recovery of iron and other metals from the EAF slag using smelt-reduction process was studied

2022年1月21日 The iron element in electric arc furnace (EAF) slag is extremely difficult to recycle due to the low specific magnetic susceptibility of the RO phase (a solid solution of FeO, MgO, CaO, and MnO). Landfilling EAF slag is strictly forbidden for environmental consideration because of poisonous Cr6+ leaching. The original RO phase could be

2021年8月1日 EAF slag filters have been utilized for the mitigation of heavy metals from a gypsum mining leachate where a high removal efficiency of 99.9% phosphorus followed by 99.3% zinc, 98.0% manganese, and 85.3% fluoride was obtained [229]. This establishes a broad-spectrum efficacy of SS filters for removing phosphate.

34429031 DOI: 10.1080/09593330.2021.1968957 Abstract Steel slag from an electric arc furnace (EAF) may contain significant amounts of oxides of valuable metals. The recovery of iron and other metals from the EAF slag using smelt-reduction process was studied with coal as the reductant.

New EAF Slag Characterization Methodology for Strategic Metal Recovery Nour-Eddine Menad 1, Nassima Kana 2, Alain Seron 1 and Ndue Kanari 3,* 1 Waste and Raw Materials andRecycling Unit, Water, Environment Process and AnalysisDepartment, BRGM, 3 Avenue Claude Guillemin, BP 36009, CEDEX, F-45060 Orléans, France; n.menad@brgm (N.

2018年1月1日 Leaching test revealed that concentrations of the heavy metals leached from the EAF slag in both tap water and rain water conditions were lower than the limit regulated by Department of ...

This process produces slag in quantities of 600–800 kg/Mg of EAF dust, equivalent to over 2 million tons of “Waelz slag” in annual world production. Slag from the Waelz process is used mainly in construction and road building (as an aggregate); in the production of cement, concrete and bricks; as a basic material for sports fields and dykes; and as a

2021年3月19日 EAF slag can be used as blending material for Portland cement, by the hydration of Portland and EAF slag mixtures. The values of compressive strength of the mixtures containing 5 and 10 wt% EAF slag were near to those of the hardened neat Portland Cement Paste at most of the hydration ages, especially at the latest, according

The effects of HCl concentrations on the dissolution EAF slag were studied at varying concentration of HCl. It is observed that the dissolution of EAF slag increased with increasing concentration of HCl at constant temperature and time. When the concentration of HCl increased from 0.5 M to 4.0 M, the dissolution increased 17.06 %. The optimum

The recovery of iron and other metals from the EAF slag using smelt-reduction process was studied with coal as the reductant. A pig iron phase with high carbon and a final slag depleted of the valuable metals were

New EAF Slag Characterization Methodology for Strategic Metal Recovery Nour-Eddine Menad 1, Nassima Kana 2, Alain Seron 1 and Ndue Kanari 3,* 1 Waste and Raw Materials andRecycling Unit, Water, Environment Process and AnalysisDepartment, BRGM, 3 Avenue Claude Guillemin, BP 36009, CEDEX, F-45060 Orléans, France; n.menad@brgm (N.

2021年8月1日 Volume 9, Issue 4, August 2021, 105640 Waste to wealth: Recovery of value-added products from steel slag Pallabi Das a , Sidhidatri Upadhyay a , Dubey, Krishnakant K. Singh Add to Mendeley https://doi/10.1016/j.jece.2021.105640 Get rights and content • Critical review of viable metal and non-metal recovery techniques from SS. •

2021年10月1日 Since 14% of produced EAF slag (26.6–39.2 million tons annually) is landfilled, it is highly desirable to find potential applications for that to enable the circular economy (make, use, recover) as an alternative to

This process produces slag in quantities of 600–800 kg/Mg of EAF dust, equivalent to over 2 million tons of “Waelz slag” in annual world production. Slag from the Waelz process is used mainly in construction and road building (as an aggregate); in the production of cement, concrete and bricks; as a basic material for sports fields and dykes; and as a

2022年7月1日 However, some researchers expressed concerns regarding using EAF steel slag as a construction material due to the presence of lime and magnesium oxide that can cause volume instability [54]. Many steelmaking factories post-treat the slags, in order to recover valuable metals that could be present as lumps inside the aggregates (mostly

2018年1月1日 Heavy metal recovery from electric arc furnace steel slag by using hydrochloric acid leaching CC BY 4.0 Authors: Lim Jin Wei INTI International University Thomas Choong Shean Yaw Abdullah...

2021年11月17日 Carbonation is an effective method to promote the quality of the steel slag binder. In this article, two carbonation approaches, namely hot-stage carbonation and accelerated carbonation, were employed to

2021年10月14日 This process produces slag in quantities of 600–800 kg/Mg of EAF dust, equivalent to over 2 million tons of “Waelz slag” in annual world production. Slag from the Waelz process is used mainly in

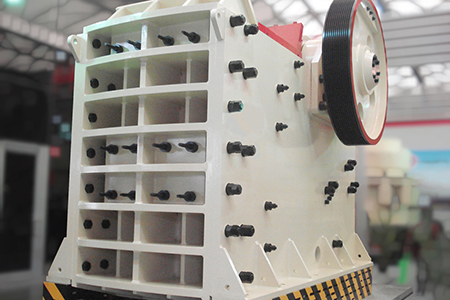

In ABS, the recovered scrap metal is approximately 3% of the processed material and is recycled back to the meltshop. 2 MATERIAL AND METHODS 2.1 EAF Slag Characterization The slag produced by the EAF is suitable for recovery and can be processed after a seasoning period, during which the waste is exposed to the weather

© Slidesigma - 2022 | All Right Reserved. Designed By Slidesigma